E-mail: info@gunsjet.eu

Tel.: +48 606 99 11 75

E-mail: info@gunsjet.eu

Tel.: +48 606 99 11 75

Textile Printers

Product Highlights:

● Original Hi-precision Epson S3200 print head, more durable and stable than Kyocera KJ4B;

● Three Models: P-Jet 1904, P-Jet 1908, P-Jet 1808

● Minimum 3.5pl Variable, Hi-speed and Hi-resolution printing;

● Linear motor impriving high productivity up to 600sqm/hr

● Mass Ink Supply and Storage Alarm Systems;

● Automatic Print Head cleaning and maintenance systems;

● Pause function for Missing material and ink;

● Strengthened feed-in system support 3000~10000m paper roller;

● Have the highest installed capacity of similar products in the market

● Stable and Simple with Quality

DESCRIPTIONS

High speed Dye-sublimation Textile Printer

Are you looking for a new dye-sublimation textile printer? For chemical fiber materials, you will need a dye sublimation printer! Dye-sublimation printing is a technique of computer printing using heat to transfer dye to materials such as paper, plastic, card, or fabric. Dye sublimation printing is an integral part of the textile market. The process creates the perfect chemistry for printing on polyester, which is one of the most popular textiles used for soft signage at tradeshows, airports and malls.

GUNSJET P-Jet is a supper fast dye-sublimation textile printer, equipped with original EPSON S3200 inkjet print head with high resolution and great color performance (4 or 8 pcs print heads optional). P-Jet textile printers are mainly used in the digital printing industry, especially for fabrics (choths) made of chemical fibers, and are suitable for mass production companies and fast growing fashion industries. When it comes to cotton, silk, nylon and all other (non-polyester) fibers, the dye sublimation paper transfer process won’t work.

We have three models: P-Jet 1904, P-Jet 1908 and P-Jet 1808, the difference are the number of print heads, and print width. The whole digital dye-sublimation printing machine adopts industrial modular design to ensure stable operation.

Basic Configuration and Technical Characteristic:

• Original EPSON S3200 print head, more durable and stable than Kyocera KJ4B

• Multiple rollers are applied in feed-in and take-up stytem to improve paper takeup aligning, and elimiate paper wrinkles

• Roll-to-roll material, the widest width 190cm

• linear motor(maglev guiderailers) is applied in X axis to ensure high resolution, stability, and fast carriage moving speed.

• Pause of paper out and alarm for shorting of ink

• Professional color management software, more accurate output color

• State-of-art industrial design concept, strong body

• Fully sealed drying system and mute fans reduce noise a lot

• Intelligent and convenient operation

• Multiple rollers are applied in feed-in and take-up stytem to improve paper takeup aligning, and elimiate paper wrinkles.

We have the highest installed capacity of similar products in China. To discover more about industrial dye-sublimation printer advantages, all you need to do is share a few details in the short form below. We would like to hear from you and we'll be in touch.

Capping station

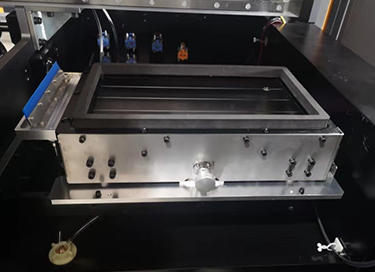

Head plate construction

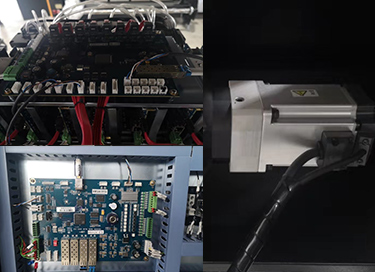

Main board and motor

Negative system for ink

5L/B Ink tank

Feeding and winding

| Model | P-Jet 1904 or 1908 or 1808 |

| Printhead | 4 or 8 pcs original Epson S3200 Printheads |

| Printing Technology | Piezoelectric inkjet, variable dot printing, grayscale technology (3.5pl) |

| High quality model | 200㎡/hr |

| High production model | 400㎡/hr |

| High speed model | 600㎡/hr |

| Ink Type | Dye-sublimation ink |

| Ink Configuratoin | 4 colors or 6 colors |

| Material | Heat transfer paper (35g - 70g) |

| Ink Supply System | Negative Pressure System (NPS) with Automatic Ink Supply |

| Max Printing Size | 1900mm |

| Image Process Software | Maintop, Photoprint, Texprint, Caldera |

| File Format | PDF, PS, EPS, TIFF, AI |

| Ink Cartridge Size | 5L |

| Printer Dimesions (X*Y*Z) | 3700 * 1700 * 1900 mm |

| Wooden Box Dimensions (X*Y*Z) | 4100 * 2000 * 2000 mm |

| Net Weight | 1800kgs |

| Power Requirement | Imput voltage: 220 ~ 240V, single-phase, 50/60HZ, 6.5KW |

| Operating Conditions | Temperature: 20~30°C; Relative Humidity: 45%~75%; |

GUNSJET digital textile printer

FAQ

Q What is the Application Range of UV Printer?

Our UV printer enjoys wide application range. Currently, it has been extensively applied to advertisement, glasspanel, wood floor, ceramic tile, suspended ceiling, electronic product shell, individualized decoration and other fields. Fordetailed application cases, please refer to printer solutions in different application fields.

Q How many mobile phone cases can you print a day?

Take LE-2513 for example, we can print Iphone case about 5000 units per day.

Q How many years can a machine last?

About 8-10 years

Q How many machines will you sell earch year?

In the year of 2016, we sold 880 units and we sold 1200 units in 2017.we are the Top 3 Ricoh manufacturer in China.

Q How about the printing cost?

1L ink can print 80 M2,it is about 1 USD per square meter printing.

Q How many people in your company?

The number of employees is 200+, and we have the R&D 30 people, technical support 60 people, production 60 people. Strong research and development ability allows constant launches of new products to keep you at the top of the league.

Q What is your company advantage?

1.Accumulating nearly a decade of experiences in UV printing industry, GUNSJET provides you professional solutions in UV printers and help you save time and effort getting into the UV market.

2.GUNSJET is a trusted manufacturer with recognition from international suppliers. We ensure stable supplies of genuine products.

3.The top 3 printheads customer for Ricoh shows that GUNSJET takes up a significant market share of Ricoh printers in the market.

4.Expansion of manufacturing site and big production capability can cater your growing demand and provide timely delivery. No need to worry about delay or no stock.

5.The sales volume and amount doubled by 100millions in 2017 shows that you will be working with a fast growing company and expand the potential business together.

Navigation

Inquire Now